Blog

Minimizing changeover time by leveraging scalable SDA services

What is an Assembly Line Changeover?

In the manufacturing industry, the time required to adjust the assembly line operations for switching from producing one product variant to another is called changeover time. A few changes that are performed during this time are system reconfigurations, tool changes, and raw material supply changes. The time required during this changeover process is a significant concern for the manufacturing industries as it results in a reduction in overall production time and reduced Overall Equipment Efficiency (OEE). This problem was, for instance, addressed by Shigeo Shingo, who introduced the method of SMED (Single-Minute Exchange of Die) in 1950, which focused on executing shorter changeover time in factories [1].

One crucial operation performed during the assemblyline changeover process is the reconfiguration of multiple PLCs. However, the current PLC reconfiguration process is hugely dependent on Automation Engineers and is a time-consuming process. This increases downtime and incurs massive production and revenue loss. Although changeover time cannot be completely eliminated, it can be reduced by using self-adaptive systems to to adjust and adapt this changeover process quickly.

At SDA we investigated the time required for the reconfiguration of multiple PLCs on a factory shop floor using the self-adaptation technique of PLC reconfigurations. Furthermore, comparison between manual adaptation and self-adaptation of PLC was evaluated to find production time and productivity gained.

Multiple PLC reconfigurations using SDA PLC Ops and Version Pro

Industries have hundreds of PLCs operating round the clock to meet the market requirements. However, managing these PLCs and keeping track of the different versions of PLC projects deployed to the PLCs requires a lot of time and human effort.

SDA Version Pro enables users to conveniently open and manage PLC projects in any browser, bringing transparency and traceability to the PLC code with advanced version control features.

SDA PLC Ops enables the backup, management and versioning of all PLCs and projects across different vendors.

In our recent blog, “Bring closed-loop automation from theory to practice,” the self-adaptation technique implementation for PLC reconfiguration in a factory environment is explained using the MAPE (Monitor Analyze Plan Execute) loop. The same loop can be implemented over multiple PLC adaptations. The assembly line changeover operation can be initiated under the following scenarios:

Scenario 1: It is assumed that the monitoring and analysis of the assembly line operations are performed, and the insights derived state the need for assembly line changeover (PLC reconfiguration).

Scenario 2: The changeover is scheduled by the management based on market requirements.

In both scenarios, new PLC codes and projects need to be deployed to multiple PLCs in order to change the machine behavior. These PLC project files can be uploaded and stored in the SDA cloud using SDA “Version Pro” solution and the deployments can be performed using SDA “PLC Ops”.

Sequential PLC deployments

SDA PLC Ops facilitates automated deployments of PLC projects to the physical PLCs for vairous PLC vendors (Siemens, Codesys, Beckoff). SDA uses AWS cloud services to manage and store PLC projects. These projects are deployed to the physical PLCs on the shopfloor with SDA’s proprietary connectivity service, which enables seamless deployments within minutes.

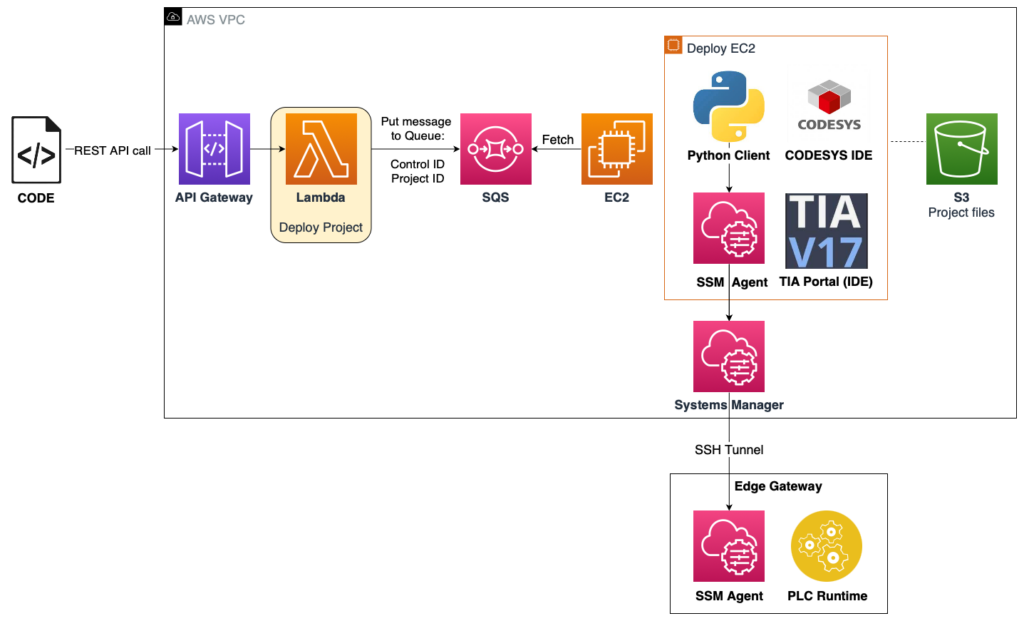

The deployments can be performed programmatically using REST API calls to the AWS services. Following is the AWS architecture used for connecting the cloud to the physical PLC and automatically deploying PLC projects from cloud directly to the PLC runtime.

The AWS EC2 service helps open the PLC project to be deployed in its respective vendor-specific IDE. The IDE compiles the project and the “Download to PLC” information is transferred to the PLC runtime on the shopfloor using AWS Systems Manager. It communicates with the PLC runtime using SSM Agents both in the EC2 and the edge gateway via an SSH tunnel. The download information is transferred from the SSM agent running in the EC2, to SSM Agent running on the Edge gateway via Systems Manager. Since the PLC and the edge gateway are in the same local network, the information is passed to the PLC and the program is executed by the PLC runtime.

Using this deployment architecture, the user can initiate multiple deployments to PLCs irrespective of the PLC vendor and IDE restrictions. This is a sequential process, and only one deployment is executed at a time. Using the results for this self-adaptation technique for reconfiguring of a PLC from the blog “Bring closed-loop automation from theory to practice”, the total time required for this individual PLC adaptation is 6 minutes 40 seconds. Hence, we can perform sequential deployments one after another and complete the entire changeover process for multiple PLC reconfigurations in significantly lower time than manual adaptation.

Bulk PLC deployments

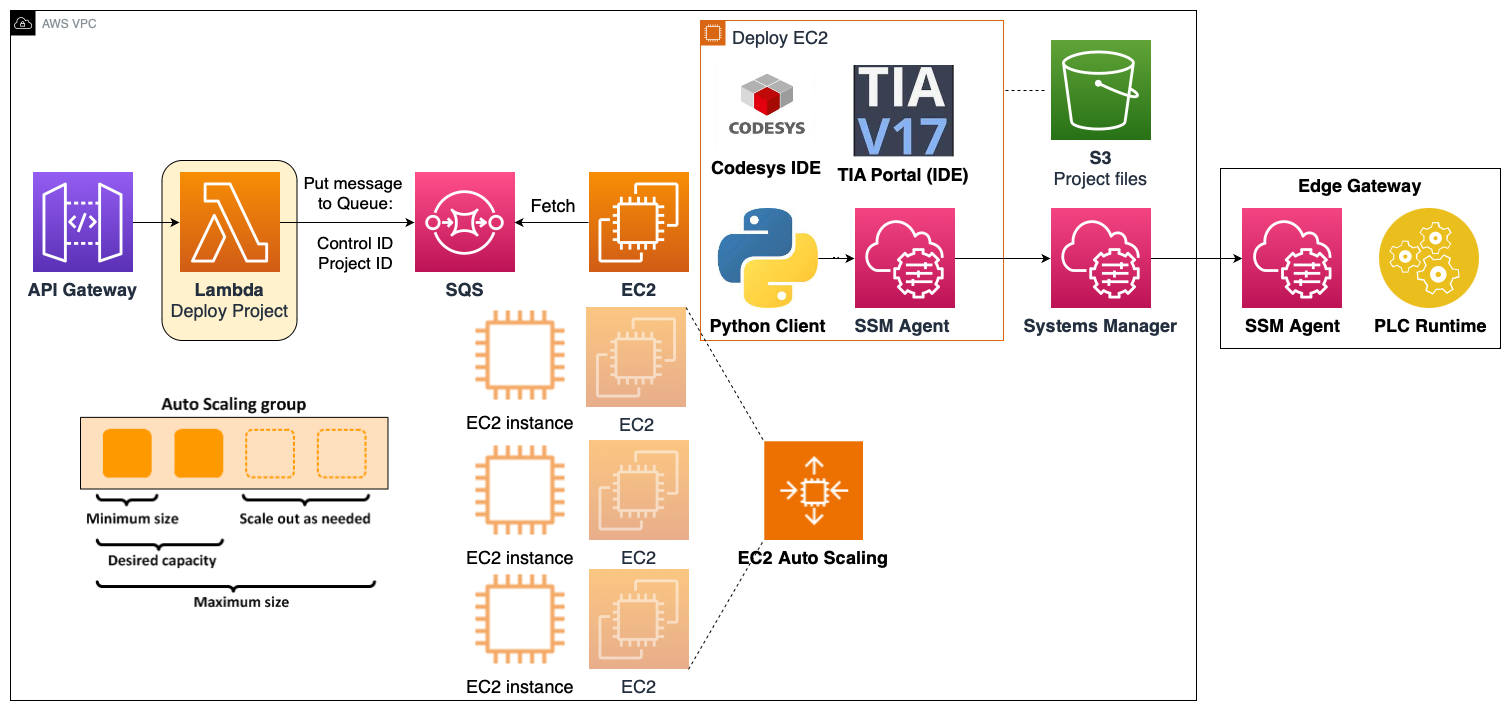

In contrast to sequential PLC deployments, deployments can also be performed in parallel. To perform multiple parallel deployments, multiple EC2 instances are required as the deployments are carried out using PLC IDEs running in the EC2. Individual EC2 carries out each deployment; hence to facilitate multiple PLC adaptations, a higher number of EC2 instances are required.

The AWS architecture for using multiple EC2 instances for deployments is shown below.

During the scheduling of assembly line changeover, it is also possible to schedule the number of EC2s which will be used for deployments. Amazon EC2 auto scaling helps in scaling up or down the number of EC2s based on the load. The minimum and maximum number of EC2s can be specified in an EC2 auto-scaling group. Policies can be set to launch or terminate instances as the demand of the application goes higher or lower.

By using multiple EC2 instances for multiple and parallel deployments, we can achieve a higher number of PLC adaptations in a very short time; however, using additional AWS services may increase the overall cost of the changeover process. This is a high-risk process as it is challenging to troubleshoot when an issue arises. Also, the monitoring of multiple PLCs to check if the deployment is successful or not will be a tedious task.

Evaluation of changeover time minimization

From our previous blog “Bringing closed-loop automation from theory to practice”, we have established the average time required for the PLC reconfiguration using the self-adaptive technique to be 400 seconds (6 minutes 40 seconds). In this blog we extend the implementation of PLC self-adaptation to multiple PLC reconfigurations using sequential and bulk deployments.

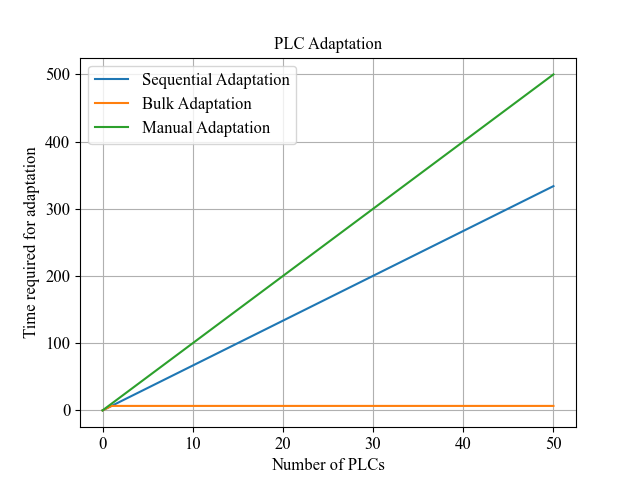

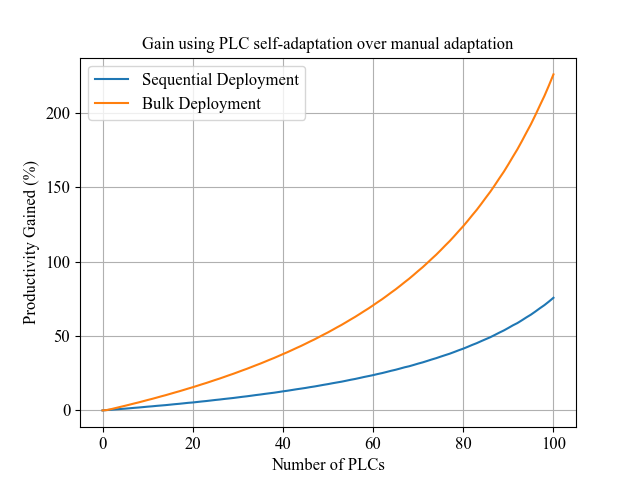

Using the base data for average self-adaptation time, we generated line charts to visualize how different types of deployments can affect the time lost or gained during an assembly line changeover. The comparison is made with time required for manual PLC adaptation which is assumed to be 10 minutes on average. For bulk deployments, it is assumed that there are an equal number of EC2s running in AWS cloud as the number of PLCs to be reconfigured.

The line chart plotted in the above figure shows the time required for PLC reconfiguration using manual adaptation, sequential adaptation, and bulk adaptation techniques. Each line shows the time required for reconfigurations over multiple PLCs (x-axis). As expected, we observe that manual adaptation takes the longest of the three types of adaptation. Sequential adaptation shows 30% reduction in time required to reconfigure multiple PLCs over manual adaptation. Bulk adaptation is deemed the fastest way of PLC adaptation as it requires a constant 6 minutes 40 seconds average time for any number of PLCs.

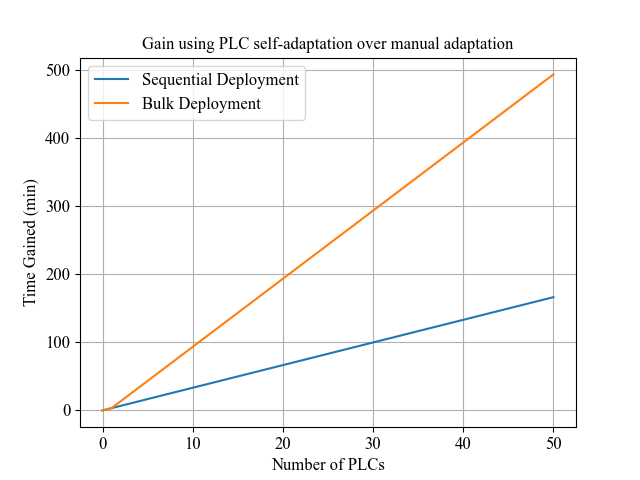

Figure 4 shows a line chart with two lines showing the time gained using the PLC self-adaptation technique with sequential and bulk deployments methods over the manual adaptation technique. We observe a linear rise in the graph with the bulk deployments technique being the more efficient in terms of time gained compared to sequential deployments.

The figure represents a line chart showing productivity gain using PLC self-adaptation techniques in comparison to manual adaptation technique. We observe exponential productivity gain in both self-adaptation techniques (Sequential deployments and Bulk deployments).

This proves that using self-adaptation techniques in factories will drastically increase the total uptime of production processes, resulting in increased production and revenue generation.

Conclusion

Overall, implementing the PLC self-adaptation technique in conjunction with the closed-loop automation process has proven to be a valuable solution for mitigating downtime, reducing human workload, and enhancing the productivity and efficiency of the factory.

The results of these experiments provide a strong foundation for adopting self-adaptive systems in manufacturing environments. With the successful exhibition of the benefits of rapid PLC reconfiguration and eliminating the human factor in performing efficient and automated factory operations, it can be anticipated that the integration of closed-loop automation with self-adaptation techniques will continue to revolutionize factory operations, leading to increased overall performance, efficient human-machine work distribution, and increased competitiveness in the rapidly evolving industrial revolution.

[1] S. Shingo, A Revolution in Manufacturing: The SMED System, 1st ed. Routledge, 1985. [Online]. Available: https://www.taylorfrancis.com/books/mono/10.4324/9781315136479/revolution-manufacturing-shigeo-shingo

Stay up to date. Subscribe for our latest news.