Blog

PLC Virtualization and Workload Consolidation

The complexity of automation systems is rising. There is an abundance of IoT and sensor systems for monitoring, real-time reporting of KPIs, and predictive maintenance. Functionalities of Programmable Logic Controllers (PLCs) are increasing, and often enough, business logic is executed on PLCs for convenience instead of isolating it from control logic. There is a mix of systems, vendors, and system integrators working together while trying to minimize cost and maximize productivity and efficiency. SDA and FLECS are partnering to resolve this complexity through virtualization and clearly defined, unified interfaces for manufacturers and machine builders.

Workload Consolidation

Virtualization and containerization of workloads reduce this complexity by eliminating hardware dependencies and providing a single platform for all workloads within one machine or factory. Instead of handling a collection of hardware and software vendors, each with their own tools, requirements, and sometimes overlapping functionality, only one hardware platform neatly allocates resources according to software needs. By stripping away the hardware layer and running the actual workload inside containers, hardware dependencies are removed. Further, resources are used more efficiently and costs are lowered.

Workload consolidation comes with its own set of requirements, as established by Intel in their 2019 white paper, in particular:

- Worst-case execution time (WCET): The longest execution time that a workload may take. This must be shorter than a specified deadline.

- Bandwidth Capability: When consolidating workloads, they may have distinct bandwidth requirements that vary over time. The peak bandwidth requirements of the workloads must be compatible.

- Logical Isolation: Especially when considering PLC workloads, logical isolation may be required to prevent interference from non-real-time workloads.

- Determinism: Generally, predictable response times and behaviors are desirable, yet above all else, for real-time and PLC workloads. This leads to specific requirements in terms of isolation and communication.

- Platform Requirements: The underlying platform must fulfill all requirements of the workloads running on it, and manage the conflicting requirements.

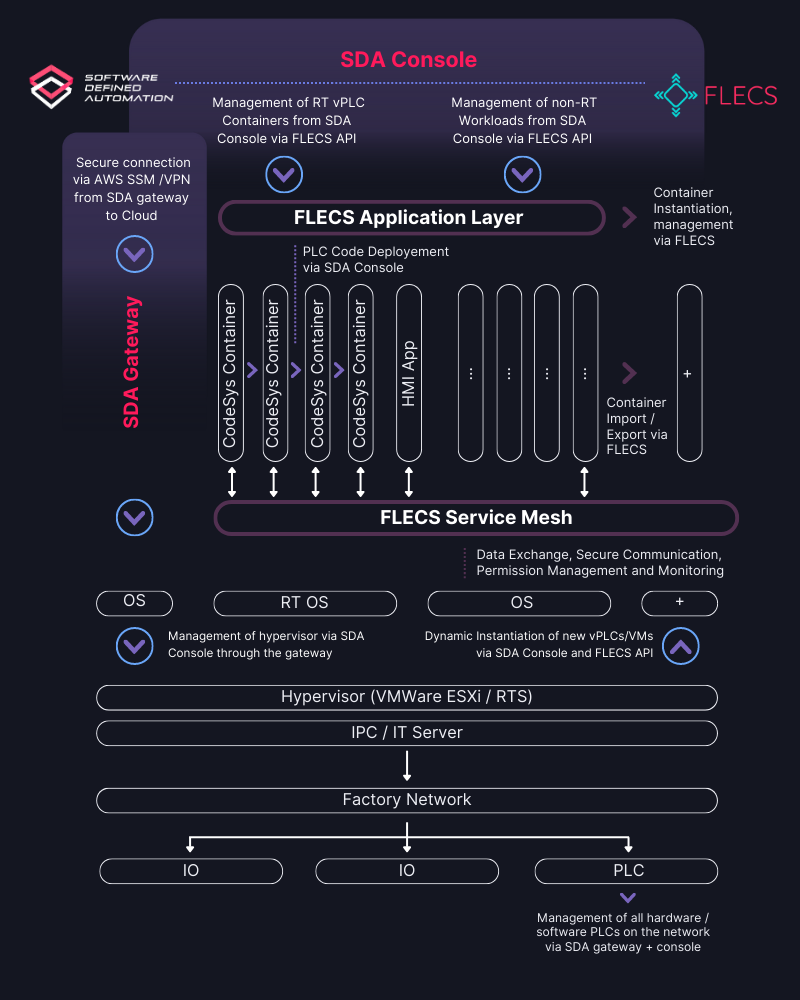

Meeting these requirements is possible only with a well-designed architecture and a platform that efficiently combines different technologies. SDA provides a unified interface for managing real-time control workloads across different vendors. Thus, workload consolidation is a key consideration for the platform, particularly to provide the factories with a convenient solution to manage a mixture of hardware- and software / virtual PLCs and the related applications in greenfield and brownfield systems. Since FLECS simplifies and automates the management of containerized apps, SDA and FLECS aim to maximize the impact of these synergies for manufacturers.

Managing your workloads

SDA and FLECS propose an architecture that consolidates real-time and non-real-time workloads on the same infrastructure: Commercial-of-the-shelf x86 server hardware which is commonly available and less susceptible to supply chain issues. It is also significantly cheaper and more powerful – a single server is computationally far ahead of any PLC.

Virtualization allows the efficient isolation of operating systems from the hardware. A hypervisor allows you to run multiple heterogeneous operating systems, e.g. real-time and non-real-time operating systems on the same hardware. Especially in brownfield applications, there are common dependencies on various operating systems. For example, porting these applications to a new operating system may be impossible or risky – running it on virtualized hardware within its own environment can resolve this predicament.

In the recent past, SDA has worked on running Soft-PLCs within virtual machines to demonstrate the feasibility of virtualizing real-time workloads. Extensive tests prove sub 10ms performance. This comes with the aforementioned benefits of cost savings, avoiding supply chain disruptions, and flexibility in how and where PLC workloads are deployed. SDA provides a unified management interface for PLC workloads, which extends to virtual PLCs. This interface provides manufacturers with the necessary capabilities to efficiently and effectively manage their PLC workloads instead of using a variety of vendor-specific tools in many versions.

New or current shop floor applications like OPC-UA servers or SCADA systems may already run within containers. Containerization further facilitates the portability of applications, thus lifting the restrictions of the operating system layer. Instead of running each application within its own operating system, multiple containers can run in parallel within a single operating system, thus further reducing the maintenance effort, cost, and overhead. FLECS reduces the complexity and effort of managing containers – or apps – by providing the FLECS service mesh and marketplace. Manufacturers benefit from the wide selection of industrial apps and always find the right solution for green and brownfield applications.

What SDA and FLECS bring to the table

With FLECS the complexity of running containers – called apps – is reduced and automated to a maximum level. Machine builders can focus on their core competencies which are using the apps to create machine applications and save up to 40% of the time. Further benefits for you as a machine builder:

- You have a free choice of hardware between PLC, IPC and server and thus save on purchasing of your PLC hardware.

- You don’t need Linux knowledge to install FLECS or apps. You also don’t need Linux knowledge for the configuration.

- You have the freedom to use the apps that suit the purpose and thus set up a system individualized to your wishes.

- Exchange data between apps easily and securely.

- You keep FLECS and all apps up to date very easily and get a secure data flow between all installed apps.

FLECS natively integrates into SDA PLC Ops solution that provides a unified interface for manufacturers and machine builders. SDA manages your PLC code and provides the cloud interface for managing your custom FLECS apps. The cloud-based single source of truth for your PLC and PLC-related data allows you to keep track of what exactly is deployed to your PLCs, who deployed it, and when. With SDA virtual PLC you can comfortably migrate your hardware PLCs to commercial-of-the-shelf IT servers. On top of that, you can enjoy even more features:

- View PLC projects and differences between versions inside the browser – without having to open your IDE.

- Run your favorite IDE in the cloud with “IDE-as-a-Service”, which seamlessly integrates existing IDEs into our single-source-of-truth

- Enhance the security of your factory with fine-grained user management

- Deploy PLC code to your PLCs with the click of a button by using our silent deploy feature

If you want to learn more about what FLECS and SDA are working on together, contact us.

References

[1] https://cdrdv2-public.intel.com/671401/isd-workload-consolidation-2019.pdf

Stay up to date. Subscribe for our latest news.